High-strength, hollow-fiber membranes

Stainless steel backwash pump

Automatic pre-treatment filter

PLC control panel

Automatic backwash

Digital flowmeter

Stainless steel skid

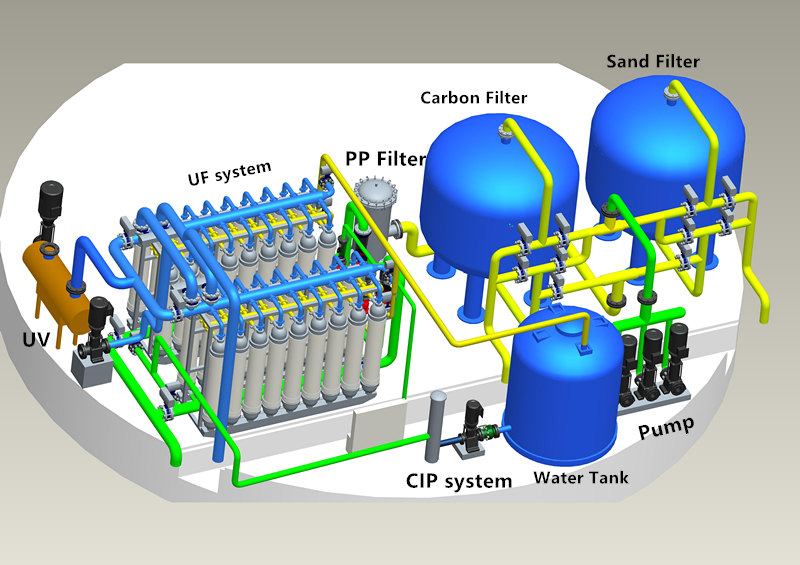

Process flow chart:

Application:

Mineral water: In the manufacture of mineral water, ultrafiltration technology is applied. In the engineering design, the pore size and type of membrane will be selected according to the water quality analysis report of mineral water source, and the ultrafiltration design will be designed.

Food: dairy products, fruit juice, wine, condiments and other food production gradually adopt ultrafiltration technology, such as milk or whey protein and low molecular weight lactose and water separation, juice clarification and sterilization, wine colored protein, polysaccharide and other colloidal impurities removal, soy sauce, vinegar bacteria removal.

Medicine: In medicine and biochemical production, it is often necessary to separate and purify heat-sensitive substances, and ultrafiltration technology shows its outstanding advantages. Using ultrafiltration to separate and concentrate biologically active substances (such as enzymes, viruses, nucleic acids, special proteins, etc.) is quite suitable for drugs (such as alkaloids, hormones, etc.) extracted from plants. There are often macromolecules or solid substances in the extract. In many cases, Ultrafiltration can be used to separate and improve product quality.

Pure water, ultra-pure water: the Primary purification of industrial water, pure water ultra-pure water preparation RO pretreatment, pure water, ultra-pure water terminal treatment.

Environmental protection: advanced treatment of industrial wastewater, urban water reuse system, electrophoretic paint, oil recovery.

Fermentation: separation and purification of biochemical fermentation broth, concentration and purification of enzymes, clarification and filtration of sugar and xylitol.